ALPHATEC greatly reduces design, manufacture and quality management time over previous by flexible utilizing the latest tools like 3 dimension solid design and flow analysis etc., while at the same time providing high quality products at low cost by learning Japanese technology and production management.

Design & Proposal strength

ALPHATEC provides proposals and support centered on 3 dimension solid design for all stages from conception to commercial production.

Integrative production from trial to mass

ALPHATEC specializes in everything from trial production to mass production, and provides trial production proposals with an eye towards mass production.

Global handling of molds and parts

ALPHATEC has established a system to respond to local procurement through collaboration between Japan and India.

- 2021/10/10

- Introduction of Projector MVB-3020 (Made by Haibo)

- 2021/10/10

- Introduction of Machining center α-D21MiB (Made by FANUC)

- 2021/10/10

- Introduction of Machining center PS105 (Made by Makino)

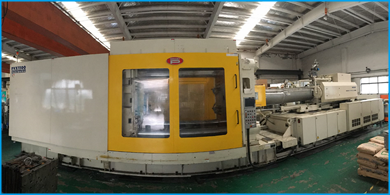

- 2017/12/29

- Introduction of 1100 ton injection molding machine (Nissei)